Basic Details

| Omtech Food Engineering | |

| siachen.com/omtechfoodengineering | |

| Educational Institution | |

| 2007 | |

| IN | |

| GJ | |

| Ahmedabad |

Communication

| Survey no.31/1 Nr. Bharudi tall plaza. Hadamtal ind Area.NH27, opp. HP petrol pump Taluka :, Gondal, Gujarat 360311 | |

| +919879670483 | |

About Business

Business Summary

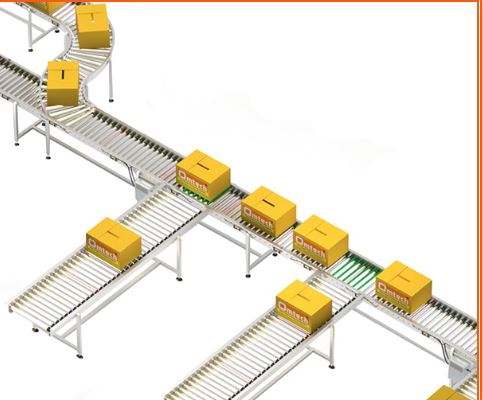

Relying on our expertise in this domain,we are engaged in offering Conveyor System Manufacturers.

Business Description

Omtech Food Engineering - A prominent company specializing in conveyor system manufacturing and supply, and it is among the foremost and largest conveyor system manufacturers - Ahmedabad, India.

At Omtech Food Engineering, we are more than just a conveyor system manufacturer; we are your trusted partner in optimizing material handling processes!!

We are one of the only largest Conveyor System Manufacturers in Rajkot India, and we offer our services as Conveyor System Manufacturers to our esteemed customers. Relying on the knowledge and skills that we have gained over the course of our time spent working in this industry.Omtech Food Engineering is pleased to provide conveyor systems that are created solely for your specifications, with no accommodations made in any way. We have a history of modifying conveyor systems and manufacturing them according to the orders of our customers. Additionally, we provide conveyor systems with specialized features and many customization choices. The rapid development of factory automation coincides with the expansion of our comprehensive selection of conveyor systems.

We are one of the only largest Conveyor System Manufacturers in Rajkot India, and we offer our services as Conveyor System Manufacturers to our esteemed customers. Relying on the knowledge and skills that we have gained over the course of our time spent working in this industry.Omtech Food Engineering is pleased to provide conveyor systems that are created solely for your specifications, with no accommodations made in any way. We have a history of modifying conveyor systems and manufacturing them according to the orders of our customers. Additionally, we provide conveyor systems with specialized features and many customization choices. The rapid development of factory automation coincides with the expansion of our comprehensive selection of conveyor systems.

We are one of the only largest Conveyor System Manufacturers in Rajkot India, and we offer our services as Conveyor System Manufacturers to our esteemed customers. Relying on the knowledge and skills that we have gained over the course of our time spent working in this industry.Omtech Food Engineering is pleased to provide conveyor systems that are created solely for your specifications, with no accommodations made in any way. We have a history of modifying conveyor systems and manufacturing them according to the orders of our customers. Additionally, we provide conveyor systems with specialized features and many customization choices. The rapid development of factory automation coincides with the expansion of our comprehensive selection of conveyor systems.

This is Our Trip:

When we first started exploring the world of conveyor systems, we had a straightforward but lofty goal in mind: we wanted to design conveyor systems that were customized to meet the specific requirements of each of our customers without sacrificing quality in any way. In order to establish ourselves as a preeminent brand in this sector, we spent a lot of time honing our skills, broadening our product range, and improving the efficiency of our operations.

Our Primary Items and Services:

Our extensive inventory of conveyor systems is designed to meet the requirements of a wide variety of business sectors. We have a solution that is tailored specifically to your industry, whether you are in the food processing industry, the automotive industry, or the logistics business. Here are some of our most fundamental products and services:

Belt Conveyors: Belt conveyors are the workhorses of the material handling industry, and here at Omtech Food Engineering, we have mastered the art of developing and constructing these flexible and adaptable systems. Our belt conveyors are not simply conveyance equipment; rather, they are the outcome of precise engineering designed to improve the facility's overall efficiency and production.

2. Roller Conveyors: Roller conveyors from our company are an excellent option for use in situations in which the movement and accumulation of products must be precisely regulated. These conveyors are built to easily and accurately move a wide range of products, from lightweight items to large loads, regardless of their size or weight.

3. Conveyors That Use Screws: In a number of different industries, including agriculture and the food processing industry, screw conveyors are an essential component. We are able to manufacture screw conveyors to meet your specific requirements, making it possible to transfer granules, powders, and bulk materials with ease.

4. Conveyors for Chains: Our chain conveyors are your reliable allies when it comes to the heavy-duty material handling tasks you need to complete. Because these sturdy systems were designed to easily manage huge and cumbersome products, they are ideally suited for use in industrial and automotive industries, amongst others.

5. Conveyor Systems That Are Modular: Our modular conveyor systems are meant to be adaptable, which is necessary in a world that places a premium on flexibility and scalability. Because these systems can be readily modified to adapt changes in your production line, you can rest assured that you will continue to stay one step ahead of the competition.

Picture Source: Business Owner's Profile

Our Dedication to Maintaining High Standards:

At Omtech Food Engineering, quality is not merely a catchphrase; rather, it is the driving force behind all we do. Conveyor systems play an important part in the operations that you run, and we are aware of this fact. As a result, we take our obligation to provide solutions that are dependable and long-lasting very seriously.

This is how our manufacturing process works.:

Each and every one of our conveyor systems is a work of art thanks to our highly talented crew and our cutting-edge production facility, which is outfitted with the most advanced technology available. Our method is an illustration of precision and commitment at every stage, from the initial idea to the finished product.

Exceptional Merits and Available Choices:

We are aware that no two companies are exactly alike in their operations. Because of this, we understand that you may require conveyor systems that come equipped with a variety of unique features and customization choices. We can provide everything you need, whether it be a specific sensor, a variable speed control, or a one-of-a-kind material for the conveyor belt.

Help With More Than Just Sales:

Our dedication to your success at Omtech Food Engineering extends much beyond the simple sale of a conveyor system. In order to guarantee that your business functions without a hitch, we provide all-encompassing support, which includes assistance with installation, maintenance, and technical matters.

Taking Advantage of Factory Automation:

The automation of factories is not a luxury anymore; rather, it is a requirement. We are aware of this shift in paradigm and are actively participating in the development of conveyor systems that can interact easily with various automation technologies. Your assembly line will operate at a higher level of productivity than ever before as a result of the smoother connection that our solutions are designed to promote with robotic arms, sensors, and control systems.

An Approach That Is Sustainble:

The concept of sustainability is more than simply a catchphrase; it should be treated as a duty. We are committed to minimizing the impact that our business activities and goods have on the surrounding environment. Our conveyor systems are created with the goals of maximizing energy efficiency, minimizing waste, and having a light footprint on the environment.

Reach Across the World, Dedication in the Community:

Even though we have customers all around the world, our headquarters will always be in Ahmedabad, India. Our dedication to the neighborhood goes well beyond mere financial contributions. We take an active role in activities that are designed to improve the region and contribute to its overall growth.

Get in Touch With Us!

Omtech Food Engineering is here to help you whether you are a seasoned industry veteran or a beginner trying to maximize the way in which you handle your material, whatever your situation may be. We encourage you to get in touch with us so that we can discuss the ways in which our conveyor systems may take the efficiency of your operations to entirely new levels.

The final word:

We are not simply a conveyor system manufacturer here at Omtech Food Engineering; rather, we are committed to being your business's dedicated partner in improving its efficacy and production. In the extremely competitive field of conveyor systems, we have managed to carve out a specific area for ourselves thanks to our unwavering dedication to quality, innovation, and personalization.

You are cordially invited to accompany us on this thrilling adventure as we continue to expand and mature in the direction of a future that is more mechanized, effective, and environmentally friendly.

For more information, please call us on phone at +919879670483 or visit our website here: Omtech Food Engineering

Products / Services

Services

- Belt Conveyors

- Roller Conveyors

- Screw Conveyors

- Chain Conveyors

- Modular Conveyor Systems

Platform Enhanced Sections and Articles

Article by Siachen Editors to aid the customer in decision making

A Comprehensive Guide to Evaluate a Vendor for Food Conveyor Systems:

Written for the client guidance by Siachen editors to help the potential customers of this business in evaluating and zeroing down on the best provider to place the order.

Introduction:

Selecting the right vendor for your conveyor system needs is a critical decision that can significantly impact the efficiency and productivity of your business. To aid your decision-making process, we have compiled an extensive guide outlining key factors to consider when evaluating potential vendors for the following product categories:

Belt Conveyors:

1. Customization and Design Expertise:

Customization Options: Does the vendor offer tailored solutions to meet your specific needs, such as different belt materials, widths, and lengths?

Design Capabilities: Are they equipped to design conveyor systems that match your industry's unique requirements, whether it's for food processing, manufacturing, or logistics?

2. Quality and Durability:

Material Selection: What materials are used in the construction of the belt conveyors? Is the quality of these materials suitable for your application?

Testing and Certification: Does the vendor adhere to industry standards and possess relevant certifications for quality and safety?

3. Operational Efficiency:

Speed Control: Can the conveyor system be adjusted to match the pace of your production line?

Energy Efficiency: Are there energy-saving features in place to reduce operational costs?

4. Maintenance and Support:

Maintenance Requirements: What maintenance procedures are necessary, and how often? Is the vendor's system designed for easy upkeep?

Customer Support: Does the vendor provide technical assistance and support services after installation?

Roller Conveyors:

1. Roller Type and Selection:

Variety of Rollers: Does the vendor offer a range of roller types, including gravity rollers, powered rollers, or tapered rollers, to suit your application?

Customization: Can you choose the roller diameter and material for your specific needs?

2. Sturdiness and Load Capacity:

Frame Design: What kind of frame or chassis supports the rollers, and is it suitable for the expected load capacity?

Safety Measures: Are safety features such as guarding and emergency stop systems in place?

3. Customization and Flexibility:

Layout Adaptation: Can the vendor adapt the layout and configuration of roller conveyors to accommodate changes in your production line?

Integration with Automation: Are these systems compatible with automation technologies?

4. Reliability and Maintenance:

Longevity: How durable are the components used in the roller conveyor system? Will it stand up to the demands of your operation?

Maintenance: What are the maintenance requirements, and does the vendor provide guidance or support?

Screw Conveyors:

1. Auger Design:

Custom Augers: Can the vendor customize the auger design to optimize material flow for your specific application?

Material Selection: Are the materials used in the screw conveyor construction suitable for your transported materials?

2. Efficiency and Consistency:

Material Handling: Does the screw conveyor efficiently move bulk materials, granules, or powders while maintaining consistent flow?

Safety Measures: Are there safety features in place, such as protective guarding and emergency stop systems?

3. Durability and Longevity:

Component Quality: Are the components used in the construction of the screw conveyor built to last in challenging environments?

Maintenance Needs: What are the maintenance requirements, and how often is maintenance needed?

Chain Conveyors:

1. Chain Selection:

Chain Type and Size: Does the vendor offer a variety of chain types and sizes to accommodate different product weights and sizes?

Material Quality: Are the chains made from high-quality materials suitable for heavy-duty applications?

2. Safety and Reliability:

Safety Features: Are safety measures in place to protect workers and prevent accidents, such as guarding and emergency stop systems?

Downtime and Reliability: How reliable are the chain conveyors, and what is the expected uptime?

3. Customization and Adaptability:

Custom Design: Can the vendor customize the chain conveyor layout and features to match your facility's requirements?

Integration: Are the chain conveyors compatible with automation systems and other machinery in your facility?

4. Maintenance and Longevity:

Maintenance Requirements: What are the maintenance needs for chain conveyors, and how often do they need attention?

Lifespan: Are these systems built for long-term use, and what is the expected lifespan of the components?

Modular Conveyor Systems:

1. Flexibility and Adaptability:

Reconfiguration: Can the vendor easily adjust the layout and functionality of modular conveyor systems to meet changing production needs?

Expansion Capabilities: Are these systems designed to accommodate future growth and changing product lines?

2. Automation Integration:

Automation Compatibility: Can the modular conveyor systems seamlessly integrate with robotic arms, sensors, and control systems to enhance efficiency?

Communication Protocols: How effectively do these systems communicate with other automated equipment in your facility?

3. Component Quality:

Durability: Are the components of the modular conveyor systems built to withstand the rigors of industrial use and adapt to various applications?

Maintenance: What are the maintenance requirements, and does the vendor offer support for upkeep and servicing?

4. Environmental Responsibility:

Energy Efficiency: Are there energy-saving features in place to reduce your facility's environmental impact?

Sustainable Materials: Does the vendor prioritize using sustainable and eco-friendly materials in the construction of modular conveyor systems?

Conclusion:

Evaluating potential vendors for conveyor systems is a multifaceted process that involves assessing customization capabilities, product quality, operational efficiency, maintenance requirements, and long-term support. By considering these factors, you can make an informed decision that aligns with your specific industry needs and production goals. Remember that the right vendor is not just a supplier; they are a partner in optimizing your material handling processes, enhancing efficiency, and ultimately contributing to the success of your business.

Last five profiles from the category:

-

Heywood Electrical – Electrical contractor and maintenance service provider in Merseyside, United Kingdom.

siachen.com/heywoodelectricalsons

Unit S5 Faraday Road, Britonwood Trading Estate, Knowsley, Kirkby L33 7YN land_line : +0151546 5585 -

Riverbend Homes – Custom home builders in Texas Hill Country specializing in personalized dream homes – Spicewood, TX, USA.

siachen.com/bennely45

21413 Vista Estates Drive, Spicewood, TX, 78669, USA land_line : +5124680240 -

Full Circle Technical Services – Leading fit-out company in Dubai specializing in property transition services – Dubai, United Arab Emirates.

siachen.com/fullcirclecollc

Al Abraj St Blue Bay Tower, Office 214 - Dubai - United Arab Emirates land_line : +971553635500 -

Emerald Training – Leading provider of forklift and haul truck licences in Brisbane, Australia.

siachen.com/emeraldtraining

PO Box 279 Virginia QLD 4014, Australia. land_line : 1300 705 821 -

McLine Studios – Leading provider of cutting-edge drafting solutions for Architects, Builders, Contractors, and Manufacturers on a global scale – Middletown, Delaware, USA.

siachen.com/mclinestudios

600 N Broad St Suite 5 #3441 land_line : +1302364089