Basic Details

| Honeywell Hydraulics | |

| siachen.com/honeywell | |

| Privately Held | |

| 2010 | |

| Mr. Ketan Panchal | |

| CEO | |

| IN | |

| GJ | |

| Ahmedabad |

Communication

| Shed no. 8, Pelican Estate., Road no. 5, Behind Gopal Charan Estate, Kathwada GIDC, Ahmedabad- 382430 | |

| +919924343873 | |

About Business

Business Summary

We offer complete Hydraulic solutions to sectors like Injection Moulding Industries, Roto moulding Industries, Rolling Mill Industries.

Business Description

Honeywell Hydraulics - A Premier Producer of Hydraulic Cylinders and Hydraulic Systems; Upholding Business Operations in Compliance with Global Standards - Ahmedabad, India.

At Honeywell Hydraulics, we take immense pride in being a leading manufacturer and supplier of hydraulic cylinders and systems!!

Before we begin:

Honeywell Hydraulics has established itself as a leading example of excellence in hydraulic engineering in an era in which precision, efficiency, and dependability are of the utmost importance. Our objective is quite clear: to provide all-encompassing hydraulic solutions to a wide range of different sectors. Our hydraulic systems play an essential part in ensuring that our business activities are carried out in a smooth and effective manner across the board, from Injection Moulding to CNC Machines, Rolling Mills to Printing, and beyond. Our journey, which started in Ahmedabad, India, has led us through a number of significant milestones as we've expanded to satisfy the ever-changing demands of a wide variety of industries, including manufacturing, waste management, heavy equipment, and automation, among others. In this company profile, we will delve into the subtleties of Honeywell Hydraulics, studying our products, our devotion to quality, and our everlasting determination to complying to worldwide standards. Honeywell Hydraulics was founded in 1871 and is headquartered in Honeywell, Ohio.

The Scope of Our Offerings:

Cylinders Hydraulic in nature:

The hydraulic cylinder is our primary offering and serves as the driving force behind our business. We have a wide variety of hydraulic cylinders, each of which can be customized to cater to the particular requirements of one of our cherished clientele. These are the following:

Hydraulic Cylinder with Flange-Mounted Mounting: Our company specializes in the production of hydraulic cylinders with flange mounting, and we provide a choice of customization options to meet the requirements that are unique to your industry.

Cylinder Hydraulic for Press Use: Our Hydraulic Cylinders for Press Machines have been built to give the precise force and durability that is required for the applications in which they will be utilized. Press machines are the backbone of many different industries.

Hydraulic Cylinder with a Double Acting Valve: We provide a complete selection of Double Acting Hydraulic Cylinders, which are highly regarded for both their dependability and their level of productivity.

Hydraulic Cylinder with a Single Acting Valve: We are really proud of our Single Acting Hydraulic Cylinders, which were developed in order to fulfill the specific necessities that are associated with a wide range of applications.

Cylinder for the Hydraulic Tie Rods: Honeywell Hydraulics is capable of producing high-quality Hydraulic Tie Rod Cylinders, which are an excellent choice for circumstances in which there is a restricted amount of space.

Hydraulic Cylinder with Clevis Mounting Clevis: Our Clevis Mounting Hydraulic Cylinders were developed for use in applications that call for a certain kind of mounting. This ensures that the cylinders will fit properly and will function to their full potential.

A cylinder for hydraulic fluids Mounting on a Trunnion: Trunnion Mounting Hydraulic Cylinders are the result of painstaking craftsmanship and are designed to deliver a consistent and dependable performance in a variety of applications, including passenger lifts.

Hydraulic Cylinder Used for Lifting Passengers:

The job of ensuring the safety and dependability of passenger lifts is one that we take very seriously, and the Hydraulic Cylinders for Passenger Lifts that we offer are evidence of our dedication to meeting that role. Our complete product line is made from premium base materials, which have been painstakingly sourced from the most reputable suppliers in our industry. Our consistent commitment to quality starts with small steps, including making sure we only use the highest-quality components in our products.

A Dedication to Achieving Quality:

Honeywell Hydraulics places a strong emphasis on ensuring that all of our products continue to meet the highest standards of quality possible. Our quest toward quality that is unmatched in the industry begins with the careful selection of all of the raw materials. We are aware of the fact that the quality of the components used in the production process has a direct bearing on the quality of the final product. Because of this, in order to acquire products that are up to the highest standards, we have partnered with some of the most reputable vendors in the sector. The dedication to quality that we have made is under the watchful eye of our quality control staff. These committed individuals remain watchful throughout every stage of the production process, making certain that every component, every weld, and every connection satisfies our strict quality standards. Every member of our team is instilled with the idea that quality control is more than just a process; rather, it is a way of thinking that guides all of our work.

Picture Source: Business Owners Profile

Observance of International Regulations and Standards:

Our persistent commitment to adhering to international standards is one of the defining characteristics that set us apart. Adherence to these standards is not an option in today's increasingly interconnected society; rather, it is a requirement that must be met. Honeywell Hydraulics acknowledges the significance of this fact, and we can claim with great pride that our business practices are in accordance with international standards in the following ways:

Certification to the ISO 9001:2015 Standard: We are very pleased to announce that we have been awarded the ISO 9001:2015 accreditation, which serves as evidence of our dedication to quality management systems. This certification is a daily reminder of our responsibility to produce products and services that not only meet but also exceed the expectations of our customers.

Standards Particular to the Industry: The many commercial sectors each have their own distinct sets of rules and laws. Our customers have the peace of mind they need because we guarantee that the hydraulic solutions we provide are designed and produced to meet or surpass the criteria that are particular to their industry.

Being Responsible for the Environment: We are aware of the significance of maintaining the integrity of the natural environment. Throughout the many stages of our manufacturing process, we make every effort to limit the amount of waste produced and our overall carbon impact. Our dedication to environmental stewardship serves as a demonstration of our intention to create a future that is both cleaner and greener.

The Industries That We Cater To

Honeywell Hydraulics is happy to service a wide variety of different industries, and we always make sure that each hydraulic solution we offer is tailored to match the particular requirements of our customers. Some of the most important industries that we work with are as follows:

Manufacturing Companies That Use Injection Molding: In the field of injection molding, which requires a high level of precision, our hydraulic systems play an essential part in ensuring that our operations are accurate and effective.

Roto Moulding Industries, Limited: The roto molding process requires dependable hydraulic solutions, and we are able to provide those.

Industries Revolving Around Rolling Mills: Our hydraulic cylinders are developed to suit the precise and long-lasting requirements of the rolling mill sector, which is why this industry is so important to us.

Printing and Publishing Industries: The printing business places a premium on both accuracy and speed, and the efficient operation of printing presses is a direct result of the hydraulic systems that we have installed.

The use of CNC Machines: The level of precision that is required for CNC machines is unrivaled, and our hydraulic systems can meet or exceed these stringent requirements.

Press for Extrusion: Industries that use extrusion processes can profit from our hydraulic systems since these systems allow exact control over the shape of materials.

Applications Requiring Shearing and Bending: Our hydraulic cylinders provide efficiency and accuracy for tasks like as shearing and bending that are required in certain applications.

Brick Making Equipment: The production of bricks calls for a balance of power and accuracy, and our hydraulic systems are able to provide both of these qualities.

Applications for the Plywood Press: In order to maintain both the product's quality and its integrity after it has been manufactured, our hydraulic solutions are used in plywood press applications.

Applications Related to Baling: Our solutions are up to the challenge of meeting the requirements of baling applications, which call for powerful hydraulic systems to manage the compression and bundling of materials.

Applications for Press Use: Hydraulic presses are used in a wide variety of sectors for operations such as stamping, shaping, and other processes; our Hydraulic Cylinders for Press Machines are designed specifically for these kinds of tasks.

The Management of Waste: Our hydraulic systems provide the necessary strength and dependability for efficient trash handling and processing, making them an invaluable asset in the important sector of waste management.

Transportation of Goods: In many different types of businesses, effective material handling is of the utmost importance, and the application of our hydraulic solutions is an essential component in guaranteeing the uninterrupted flow of goods.

Applications in Industry (Industrial): Honeywell Hydraulics' solutions find use in a wide variety of different industrial contexts and contribute to the efficient functioning of both large machinery and the production processes involved in making those machines.

Heavy machinery and tools: Heavy machinery requires hydraulic systems that are both robust and reliable, and we are able to provide exactly that for our customers.

Industries of Automated Control: Our hydraulic systems are built with the ideas of precision and consistency in mind because automation industries rely heavily on both of these qualities.

The Difference That Honeywell Hydraulics Makes:

So, what makes Honeywell Hydraulics different from its rivals in the industry? It is not simply that we conform to international standards or that we are committed to maintaining a high level of quality. Our standing in the market is determined by the interplay of a number of significant aspects, including the following:

An Emphasis on the Customer-Oriented Approach: On this adventure, we regard our customers as partners alongside us. We place a strong emphasis on getting to know your unique requirements and providing solutions that are crafted specifically for you.

Creativity and Technical Advancement: We are not pleased with the way things are currently. We make consistent investments in research and development to ensure that we are at the cutting edge of hydraulic technology and can provide our customers with the most cutting-edge solutions possible.

A Team with Years of Experience: Our staff is by far our most valuable asset. They contribute a wealth of knowledge and a high level of skill to every project because to the decades of combined experience in hydraulic engineering that they have.

All-Inclusive Methods and Procedures: We do not merely provide things; rather, we provide comprehensive solutions. We are here for you through every stage of the process, from product conception and manufacture to assembly and ongoing upkeep.

Dependability and longevity of performance: Our goods have earned a reputation in the market for their dependability and longevity. Because we are aware that downtime can be rather expensive, our systems have been developed to ensure as little of it as possible occurs.

Support Following the Sale: The completion of a transaction is not the end of our interaction with customers. After the sale of our products, we offer exhaustive assistance to ensure that they continue to function to the highest of their capabilities.

Prices That Are Competitive: There is no requirement that quality come at an expensive price. We are able to maintain high standards for the products we provide while also maintaining affordable prices.

The final word:

Honeywell Hydraulics is more than just a manufacturer and provider of hydraulic cylinders and systems; the company's headquarters may be found in Ahmedabad, India. We are a partner in your success, a dependable supplier of solutions of the highest quality, and a symbol of your commitment to meeting international standards and maintaining quality. Our journey has been defined by inventiveness, dedication, and a never-ending quest for greatness. As we move forward, our success will continue to be driven by our unrelenting attention to quality, our adherence to international standards, and our commitment to providing excellent service to our customers. Honeywell Hydraulics is here to supply the hydraulic solutions you require, no matter what industry you work in—injection molding, waste management, heavy equipment, or any of the other diversified fields we serve—whether it be injection molding, waste management, or heavy equipment. We appreciate your consideration of us as a potential hydraulic partner.

We are excited about the possibility of being of service to you and making a positive contribution to your accomplishments.

For more information, please call us on phone +919924343873 or visit our website here: Honeywell Hydraulics

Products / Services

Products

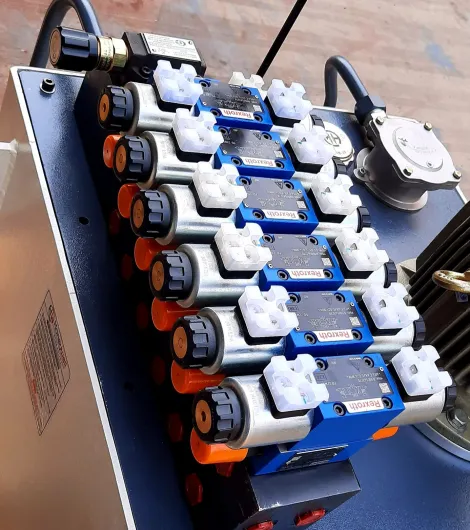

- Hydraulic Cylinder

- Hydraulic Power Packs

- Manifold Block

Platform Enhanced Sections and Articles

Article by Siachen Editors to aid the customer in decision making

A Comprehensive Guide to Evaluating Potential Vendors for Hydraulic Cylinders and Hydraulic Systems.

Written for the client guidance by Siachen editors to help the potential customers of this business in evaluating and zeroing down on the best provider to place the order.

Introduction:

Selecting the right vendor for hydraulic components and systems is a critical decision that can significantly impact the performance and reliability of your machinery and operations. To ensure a successful partnership, customers should thoroughly evaluate potential vendors. In this comprehensive guide, we'll explore the key factors to consider when assessing vendors for hydraulic cylinders, hydraulic power packs, and manifold blocks.

1. Product Quality and Reliability:

Quality Assurance: Determine if the vendor has a robust quality assurance process in place. Look for certifications such as ISO 9001:2015, which indicate a commitment to quality management.

Material Selection: Inquire about the materials used in manufacturing. High-quality materials, such as precision-machined steel, are essential for durability and longevity.

Manufacturing Standards: Ensure that the vendor adheres to industry standards and specifications, such as DIN and SAE, to guarantee compatibility and performance.

2. Product Range and Customization:

Product Portfolio: Evaluate the vendor's range of products. Do they offer a diverse selection of hydraulic cylinders, power packs, and manifold blocks suitable for your specific needs?

Customization Capabilities: Assess the vendor's ability to customize products to match your unique requirements. Custom solutions can optimize performance and efficiency.

3. Experience and Expertise:

Vendor's Track Record: Research the vendor's history and track record in the industry. A well-established vendor with a proven track record is more likely to deliver reliable products and services.

Industry Experience: Consider whether the vendor specializes in serving your specific industry, as they will have a better understanding of your unique needs.

Technical Expertise: Evaluate the technical expertise of the vendor's team. Knowledgeable engineers and technicians can provide valuable insights and support.

4. Pricing and Cost Transparency:

Pricing Structure: Request detailed pricing information and compare it to the industry average. Be cautious of significantly lower prices, as they may indicate compromises in quality.

Hidden Costs: Inquire about any potential hidden costs, such as shipping, taxes, or additional services, that may impact the overall cost of the products.

Payment Terms: Understand the vendor's payment terms and flexibility. Favorable payment terms can ease financial burdens.

5. Lead Times and Delivery:

Lead Time: Determine the expected lead time for product delivery. Delays in receiving essential components can disrupt your operations.

On-Time Delivery Performance: Request references or reviews from other customers to assess the vendor's track record in meeting delivery deadlines.

6.After-Sales Support:

Warranty and Guarantees: Review the vendor's warranty and guarantee policies. A strong commitment to post-purchase support is vital for long-term satisfaction.

Technical Support: Inquire about the availability of technical support and troubleshooting assistance. Timely support can minimize downtime.

7. Supplier Location and Accessibility:

Geographic Proximity: Consider the vendor's location in relation to your facility. A closer vendor may provide more convenient access and faster response times.

Accessibility: Evaluate the ease of communication with the vendor's representatives. Effective communication is key to addressing issues and concerns promptly.

8. Environmental and Ethical Considerations:

Environmental Impact: Inquire about the vendor's environmental practices, such as sustainable manufacturing processes and eco-friendly materials.

Ethical Standards: Assess the vendor's adherence to ethical standards in labor practices and business conduct.

Conclusion:

Selecting the ideal vendor for hydraulic components such as hydraulic cylinders, hydraulic power packs, and manifold blocks is a critical process that demands careful consideration of numerous factors. This comprehensive guide has outlined the key aspects that customers should evaluate when making their vendor selection. The quality and reliability of products, customization capabilities, vendor experience, pricing and cost transparency, and the assurance of post-sales support are fundamental elements to assess. In addition, vendor location, accessibility, and ethical standards should not be overlooked. References and testimonials, along with effective communication and responsiveness, provide valuable insights into the vendor's reputation and reliability. Risk mitigation, the vendor's financial stability, and the compatibility and scalability of their products are equally significant.

Last five profiles from the category:

-

Five Fingers Exports – Quality machinery for nonwoven bag printing and more – Coimbatore, India

siachen.com/fivefingersofficial

445, Vellalore Road, Near Top Spin Tennis Court, Singanallur land_line : +919655222655 -

Meekaj Techno App Services – Leading vacuum pumps manufacturers providing high-quality customised solutions – Ahmedabad, Gujarat, India.

siachen.com/meekajvacuumsystemspvtltd

08, Nil Tenament, Part 2, Near Haridarshan soc, New Naroda, Ahmedabad, Gujarat 382330, India. land_line : +919898257199 -

Cranedge – Specialized after sales services for cranes – Pune, India.

siachen.com/cranedgeindiapvtltd

16/3, F2 Block, MIDC, Pimpri, Pune 411 018 INDIA land_line : +918002090010 -

GTS ENVIRO India – Leading wet scrubber manufacturer providing eco-friendly solutions for air pollution control in Coimbatore, India.

siachen.com/gtsenviroindiapvtltd

18, Ambal Nagar, Near VG Rao Nagar, Ganapathy, Coimbatore – 641006 land_line : +919843030427 -

Chhajed Steel and Alloys – Supplier of Alloy 20 Fasteners for various industrial applications – Mumbai, India.

siachen.com/mukeshm

OFFICE NO 7, 42/46, MUGHBAT LANE, SHANTARAM CHAWL, MUMBAI-400 004. land_line : +919821513630