Basic Details

| Devikrupa Industries | |

| siachen.com/devikrupaindustries-2 | |

| Private Limited | |

| 2005 | |

| IN | |

| GJ | |

| Ahmedabad |

Communication

| 21, Kamal Estate, Bombay Conductor, Vatva, G.I.D.C., Ahmedabad, India. | |

| +919327488502 | |

About Business

Business Summary

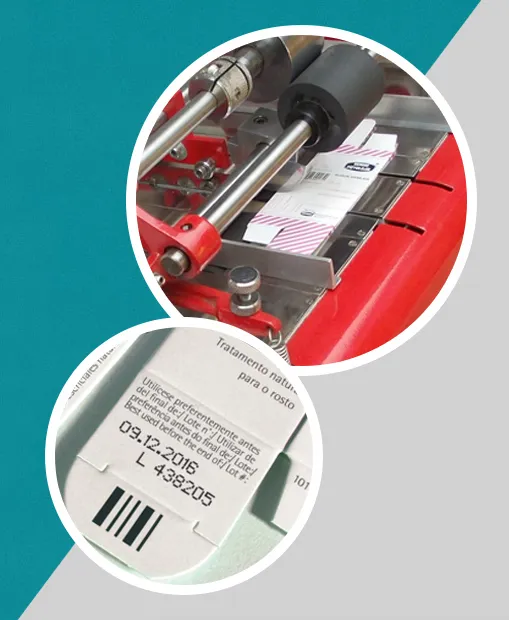

Manufacturer of Automatic Sticker Labeling Machine offered by Devikrupa Industries, Ahmedabad, India.

Business Description

Devikrupa Industries - Leading Producer and Global Distributor of Packaging Machinery; Specialized in the Fabrication and Worldwide Export of Premium Pharmaceutical Machinery – Ahmedabad, India.

At Devikrupa Industries, we take pride in our role as a prominent manufacturer, distributor, and exporter of cutting-edge processing, printing, and packaging equipment. Established in the vibrant city of Ahmedabad, India, in 2005, our company has evolved into a trusted name in the industry!!

Devikrupa Industries, located in Ahmedabad, India, is a manufacturer that provides an Automatic Sticker Labeling Machine. Greetings from Devikrupa Industries, a well-known manufacturer, distributor, and exporter of high-quality processing, printing, and packaging equipment. Our organization specializes in providing services to a variety of linked industries, including the food and beverage, cosmetics, and pharmaceutical sectors. Our mission is to satisfy the growing requirements of the pharmaceutical market, and to do so, we have constructed our business on a rock-solid foundation that was laid in 2005 by a team of specialists that have considerable experience in the field.

We at Devikrupa Industries are incredibly proud of our position as a leading manufacturer, distributor, and exporter of innovative processing, printing, and packaging equipment. Since our company's founding in 2005, when it was located in the bustling city of Ahmedabad in India, it has developed into a respected brand in the sector. We have made it our mission to cater to a varied clientele, with the majority of our business coming from the food and beverage, cosmetics, pharmaceutical, and related industries. As we begin this adventure, we would like to extend a warm welcome into our world and share with you some information about our core beliefs, accomplishments, and the factors that have contributed to our overall success.

Our adventure started in 2005, when a group of industry veterans got together to discuss how to meet the rapidly expanding demands of the pharmaceutical sector. These forward-thinking individuals had a vision for a company that would not only satisfy the rising need for processing and packaging machinery but would also establish brand-new benchmarks for quality, innovation, and customer service. As a result, Devikrupa Industries was established with the goal of eventually becoming the industry standard bearer on a global scale.

Our Most Fundamental Principles:

Quality: We are unflinching in our dedication to providing equipment of the highest possible standard. Controlling quality is one of our most important responsibilities, and we aim to achieve the highest possible standards with every item that we produce and sell.

The world of processing, printing, and packaging is always advancing, and the only way we can stay one step ahead of it is by continuously innovating. In order to maintain our clients' competitive edge in the market, our research and development team is always investigating new technologies and potential solutions.

Approach that Is Focused on the Customer: One of our core values is cultivating long-term partnerships with each of our customers. Their accomplishment is our reward, thus we place a high priority on satisfying their objectives through the provision of individualized services that are tailored to their specific specifications.

Sustainability: In this day and age of heightened environmental consciousness, we are committed to developing environmentally responsible and sustainable machinery. Our mission is to make a contribution toward a greener future while simultaneously ensuring that our operations are efficient and cost-effective.

Devikrupa Industries is not merely a local or regional player; rather, it has a global reach. We are pleased to be acknowledged as an exporter who serves customers all over the world and have broadened the scope of our operations as a result.

Machine for applying stickers automatically is included in the product portfolio

The Automatic Sticker Labeling Machine is our most well-known and successful product, and it serves as a living example of our dedication to precision engineering and technological advancement. The labeling procedure can be streamlined with the help of this cutting-edge machine, which improves both productivity and accuracy in settings where labeling is an essential stage in the production process.

The Automatic Sticker Labeling Machine has a number of features, including the following:

High-Speed Labeling: It is able to label a substantial number of products per minute, which ensures that your manufacturing lines will never have bottlenecks.

The fact that this machine can handle a wide variety of product sizes and shapes enables it to be utilized in a wide variety of business settings.

Accuracy: The labeling process has a high level of precision, which helps to reduce waste and eliminate errors.

User-Friendly Interface: It comes with a user interface that is straightforward and simple to operate, which will cut down on the amount of training time required for your team.

Low Maintenance: You can depend on this machine for constant performance, and it will only require a little amount of downtime.

The beverage industry, the food industry, and the pharmaceutical industry have all expressed their high regard for this product. It is an essential component of the operations of a great number of firms and enables them to comply with their labeling requirements in an effective manner.

Picture Source: Business Owners Profile

The Industries That We Cater To:

Devikrupa sectors has had a substantial influence on a variety of different sectors by meeting the unique requirements of those businesses. The smooth functioning of production lines, the maintenance of quality standards, and the promotion of efficient packaging are all made possible by our machinery, which plays a crucial role in all three of these areas.

1. The Pharmaceutical and Healthcare Industry: Precision and cleanliness are of the utmost importance in the pharmaceutical industry. Our gear makes it possible for pharmaceutical businesses to adhere to the industry's strictest quality guidelines while also ensuring that their products are correctly labeled. We have an understanding of the regulatory requirements that must be met in this industry, and we take measures to ensure that our equipment meets worldwide standards.

2. The Food and Drink Manufacturing Industry: It is essential for businesses operating in the food and beverage industry to adhere to the standards governing product labeling and produce products that are appealing to the eye. Because it can accommodate such a wide variety of packaging and labeling requirements, the Automatic Sticker Labeling Machine that we provide is an excellent option for use in this industry.

3. The industry of cosmetics: Labeling for cosmetic items typically needs to be both sophisticated and appealing in order to catch the attention of the consumer. Our labeling machine is highly skilled at delivering cosmetic products with a polished and aesthetically pleasing finish, which assists businesses in standing out on the shelf.

4. The industry of packaging: The speed, precision, and adaptability of workers are essential to the packaging sector. Because our gear satisfies all of these standards, we are able to facilitate the packaging of a wide array of products, ranging from pharmaceuticals to consumer goods, in an effortless manner.

5. The Market for Exports: Because of our presence across the globe, we are able to service customers in a variety of nations. We are sensitive to the fact that our customers come from all over the world and make it a point to collaborate closely with them in order to develop products that are specifically suited to their requirements.

Our Places of Manufacturing Capability:

We have made substantial investments in cutting-edge production facilities in order to guarantee that the quality of our goods is of the very best standard. Our manufacturing process integrates cutting-edge technology and handcrafted expertise in equal measure. The following are some of the most notable features of our manufacturing facilities:

Advanced Machinery: Each of our production units is outfitted with cutting-edge machinery, such as computer numerically controlled (CNC) machines and automated assembly lines, to ensure that our goods are accurate and consistent.

Skilled Workforce: Our team of engineers, technicians, and support staff are committed to providing the highest quality results and have received extensive training in this area. They are the pillars upon which our manufacturing process is built.

Control of Quality: The quality control procedure is an essential component of our production workflow. Each product is put through exhaustive testing and inspection to ensure that it lives up to our exacting quality standards.

Our production process now incorporates sustainable methods, such as recycling and the use of energy-efficient equipment, which enables us to reduce our carbon footprint while simultaneously producing machinery of the highest quality.

The Activities of Research and Development:

At Devikrupa Industries, we place a high priority on innovation, and our Research and Development (R&D) division plays a significant role in the process of bringing new ideas to life. Our research and development team is always looking into new techniques and approaches to find ways to make our goods better and come up with innovative answers. A few examples of our successes in R&D are as follows:

Innovations in Automation: We have developed more advanced automation solutions so that our machines are easier for users to operate and operate more efficiently.

Energy Efficiency: We are constantly working to improve the energy efficiency of our equipment in order to bring down the overall operational costs for our customers.

Customization: We are able to provide a great degree of customization to our products in order to fulfill the requirements of individual customers, and this is made possible by the R&D innovations that we have developed.

Initiatives Regarding Sustainability: We are doing research and putting into practice environmentally responsible procedures in the design of our machines in order to address concerns about the environment on a global scale.

Our Dedication to Promoting Environmental Stewardship:

Devikrupa Industries has made the decision to become a responsible corporate citizen in this day and age, when worries about the environment are of the utmost importance. We are motivated by a desire to lessen the negative impact that both our operations and those of our customers have on the environment. This is how we make a contribution to the preservation of the environment:

Materials That Are Friendly to the Environment: We place a high priority on using materials that are friendly to the environment in our machines. This helps to ensure that our goods have a small negative impact on the environment.

Energy Efficiency: Our equipment is built with energy efficiency in mind, which helps our customers cut down on their overall energy usage and lowers the costs of running their businesses.

Recycling Initiatives: We have included recycling programs into our production facilities, with the goals of cutting down on waste and advancing the cause of a circular economy.

Compliance with Environmental Regulations: We stay current on the most recent environmental regulations, and we check to see that our equipment complies with the criteria set forth in these regulations.

Our presence across the world has grown significantly over the years. Today, our sphere of influence spans many countries, and we have established robust ties with customers residing in a variety of geographic areas. The success that we have had in the export market is a direct result of our dedication to quality and innovation. We are pleased to be a part of enterprises all over the world and to help to the expansion and success of those businesses.

Approach that Is Focused on the Customer:

Our commitment to the satisfaction of our customers drives everything that we do. We are aware that every company operates in a unique manner and has a distinct set of obstacles in order to achieve its objectives. Because of this, we employ an individualized strategy in order to fulfill their particular requirements. The following is how we ensure that our strategy is centered on the needs of our customers:

Our sales team engages in consultative selling, in which they work closely with customers to gain an understanding of their requirements and difficulties, and then they offer expert advice and make recommendations for suitable solutions.

Customization: We offer a great degree of customization in our products, which ensures that they are in accordance with the particular specifications that our customers have specified.

Training and Support: We give in-depth training for the employees of our clients, so that those employees will be able to run our machinery in an effective manner. Any questions or concerns can be directed to our after-sales support team, who are always ready to help.

Long-Term Partnerships: We are committed to developing long-term partnerships with our customers, recognizing that our prosperity is directly tied to theirs. We are always available to help their further growth and meet their ever-evolving requirements.

Prospects for the Future:

As we look to the future, we are dedicated to advancing our goal and making contributions that are beneficial to the success of both our customers and the industry as a whole. The following is a list of some of our long-term objectives and projects:

Expansion on a Global Scale: One of our primary goals is to broaden our presence into even more nations throughout the world and establish ourselves as a reliable brand in the processing, printing, and packaging industries.

Product Line Expansion: We are working on expanding our product line so that we can meet the ever-changing requirements of a wider variety of business sectors.

Focus on sustainability: We will keep working to reduce the negative effects that our actions have on the environment and help make the world a greener place.

Innovations in Technology: In order to provide our customers with even more cutting-edge solutions, our research and development department will continue to investigate the newest technology.

The final word:

Devikrupa Industries, with headquarters in Ahmedabad, India, has made a name for itself as a dependable business associate for companies operating in the food and beverage, cosmetics, pharmaceutical, and other related industries. Our path, which was founded on a dedication to quality, innovation, and sustainability, has brought us to the international stage. We are committed to providing our customers with the very best processing, printing, and packaging equipment, so that they may run their businesses in a more effective and environmentally responsible manner. Discover how Devikrupa Industries may be your reliable partner in achieving greatness and success in your industry by accepting our invitation to explore the world of cutting-edge machinery that we have to offer here at Devikrupa Industries.

We are excited to start on new travels, create new alliances, and continue our role as a key factor in the success of organizations all over the world. We are grateful to have you as a participant in our narrative.

For more information, please call us on phone +919327488502 or visit our website here: Devikrupa Industries

Photo & Video Media

Corporate Business Video

Products / Services

Products

- Batch Coding Machine

- Washing Machine

- Filling Machine

- Capping Machine

- Labelling Machine

- Packaging Machine

- Mixing Plant

- Packaging Ancillaries

Platform Enhanced Sections and Articles

Article by Siachen Editors to aid the customer in decision making

Key Considerations for Selecting the Right Partner to Evaluating a Potential Vendor for Export of Premium Pharmaceutical Machinery:

Written for the client guidance by Siachen editors to help the potential customers of this business in evaluating and zeroing down on the best provider to place the order.

Introduction:

In the world of business, selecting the right vendor can be a critical decision that directly impacts your company's success. When it comes to procuring products or services such as Batch Coding Machines, Washing Machines, Filling Machines, Capping Machines, Labelling Machines, Packaging Machines, Mixing Plants, and Packaging Ancillaries, a thorough evaluation process is essential. This article delves into the key considerations that customers should keep in mind while evaluating a vendor for these specific products or services.

I. Vendor Reputation and Reliability

Track Record: Evaluate the vendor's track record and history in the industry. An established vendor with a history of delivering quality products and services is often a safer choice.

References and Reviews: Seek references from previous clients and look for online reviews or testimonials. These can provide valuable insights into the vendor's performance and customer satisfaction.

Reliability: Assess the vendor's reliability in terms of meeting deadlines and maintaining consistent product or service quality.

II. Product or Service Quality

Product/Service Specifications: Thoroughly understand the technical specifications of the products or services offered. Ensure they meet your specific requirements.

Quality Standards: Check if the vendor complies with relevant quality standards and certifications, particularly in the case of pharmaceutical equipment and machinery.

Sample Testing: Request samples or demos of the products or services to assess their quality firsthand.

III. Customization and Compatibility

Customization Options: Assess whether the vendor can provide customized solutions that align with your unique business needs. Customization may be essential, especially for machinery like Mixing Plants and Packaging Ancillaries.

Compatibility: Ensure that the vendor's products or services are compatible with your existing infrastructure or systems.

IV. Cost and Budget Considerations

Price Transparency: Seek clear and transparent pricing from the vendor. Understand the breakdown of costs to avoid hidden charges.

Budget Alignment: Ensure that the vendor's pricing aligns with your budget constraints. Consider long-term costs, including maintenance and operational expenses.

Value for Money: Evaluate whether the products or services offered provide value for money in terms of quality and performance.

V. After-Sales Support and Maintenance

Warranty and Support: Inquire about warranty terms and after-sales support. A vendor with a strong support system can help resolve issues efficiently.

Maintenance Requirements: Understand the maintenance needs of the products or services and whether the vendor provides maintenance services.

VI. Technical Expertise and Training

Vendor Expertise: Evaluate the vendor's technical expertise in the field. Knowledgeable vendors can provide better guidance and support.

Training Opportunities: Determine if the vendor offers training programs for your staff to operate, troubleshoot, and maintain the machinery effectively.

VII. Lead Times and Delivery

Lead Times: Check the vendor's lead times for delivery. Delays in receiving machinery or equipment can impact your production schedule.

Delivery Options: Assess the vendor's delivery options, including shipping, installation, and setup.

VIII. Scalability and Future Expansion

Scalability: Consider whether the vendor can support your future growth by offering scalable solutions or equipment.

Flexibility: Evaluate if the vendor's products or services can adapt to changes in your business requirements over time.

IX. Regulatory Compliance (For Pharmaceutical Equipment)

Regulatory Knowledge: Ensure that the vendor is well-versed in the regulatory requirements for pharmaceutical equipment, including GMP (Good Manufacturing Practices) and FDA (Food and Drug Administration) guidelines.

Documentation: Confirm that the vendor provides the necessary documentation and compliance certificates for pharmaceutical machinery.

Conclusion:

In conclusion, choosing the right vendor for products or services such as Batch Coding Machines, Washing Machines, Filling Machines, Capping Machines, Labelling Machines, Packaging Machines, Mixing Plants, and Packaging Ancillaries is a pivotal decision for your business. A comprehensive evaluation, considering all the factors outlined in this article, can help you make an informed decision and establish a long-term and mutually beneficial partnership with your chosen vendor. Remember that vendor selection is not just a transaction; it's an investment in your company's success and future growth.

Last five profiles from the category:

-

Trajex Marketing Solutions – Providing comprehensive marketing services for startups with a focus on SMS, social media, email, SEO, and branding – Boxborough, MA, USA.

siachen.com/trajexmarketingsolutions

140 Swanson Rd, Unit 423 Boxborough, MA 01719 land_line : +8454176828 -

Clipsal – Leading manufacturer of electrical accessories, data communications, and automation products – Karachi, Pakistan.

siachen.com/clipsalelectric

Building No. 2C, Comm. St. 2B Off Khayaban-e-Jami, Phase VII DHA, Karachi-Pakistan. land_line : 923471106374 -

User Umbrella – Your foundation for brilliant marketing ideas and exceptional digital services – Bangalore, India.

siachen.com/userumbrella

487, 12th A Main Rd, Sector 7 HSR Layout, Bangalore, India 560102. land_line : +919886890004 -

Pexelar – Your digital marketing wizards for top-tier SEO, website design, and management services – Noida, India

siachen.com/pexelar

201301, Noida,Uttar Pradesh, India land_line : +919621414639 -

Ken Research – Global leader in market intelligence and strategic consulting services, empowering businesses with expert analysis. Located in Gurgaon, Haryana, India.

siachen.com/kenresearch

Unit 14, Tower B3, Spaze I Tech Business Park, Sohna Road, sector 49 Gurgaon, Haryana - 122001, India land_line : +919871552944